How to Choose the Right Thickness of Expanded Metal Mesh

By Zain Corporation | February 17, 2026 | Category: Expanded Metal Mesh

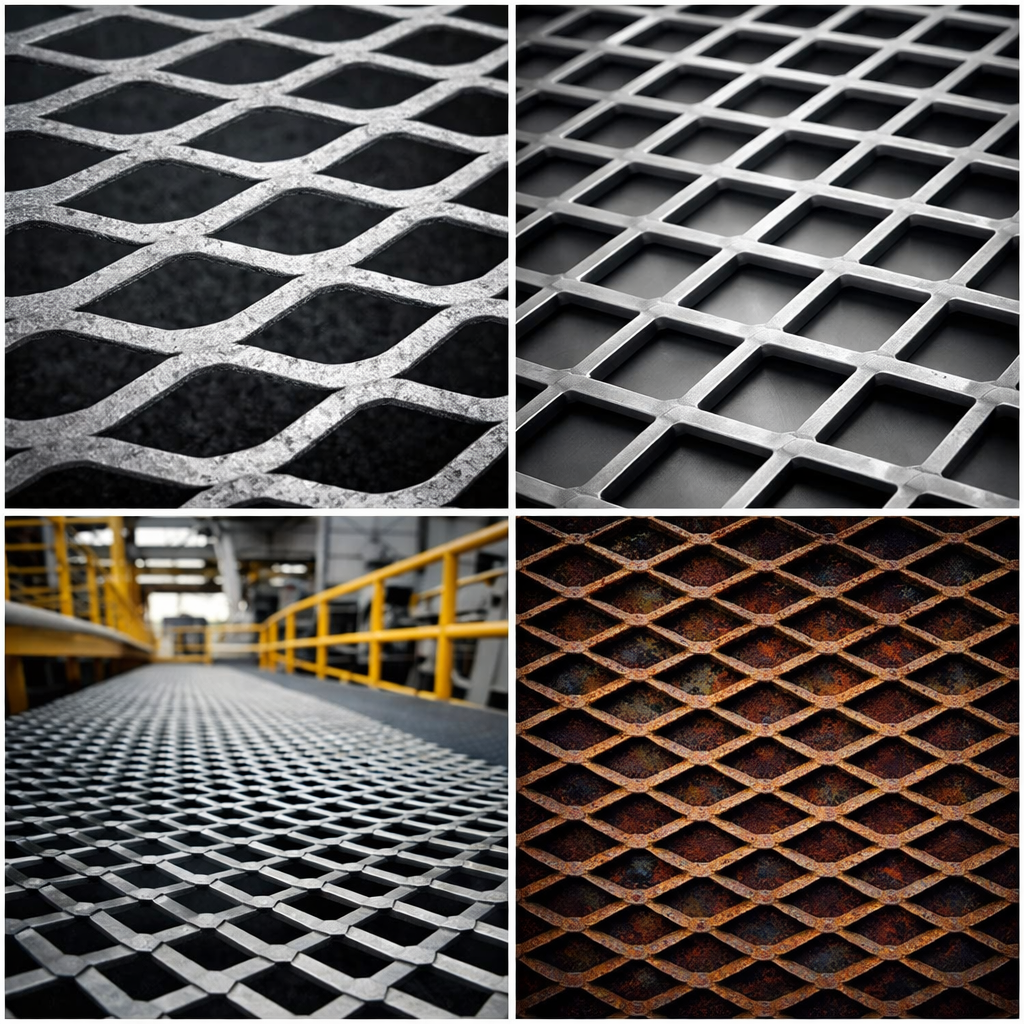

Expanded metal mesh is widely used in construction, industrial, and architectural applications because of its strength, durability, and versatility. However, selecting the right thickness is critical to ensure performance, safety, and cost-efficiency. Whether you are sourcing from an expanded metal mesh supplier in India or working with an expanded mesh manufacturer in Pune, understanding thickness selection will help you choose the most suitable material for your project.

What Does Thickness Mean in Expanded Metal Mesh?

Thickness refers to the gauge or sheet thickness of the metal used before it is slit and expanded into mesh. This directly affects the load-bearing capacity, rigidity, and overall durability of the mesh. Thicker mesh offers higher strength and impact resistance, while thinner mesh is lighter, easier to install, and more economical.

Expanded metal mesh is available in different material types, including expanded mild steel mesh, expanded steel mesh, and expanded stainless steel mesh. Each material behaves differently even at the same thickness, so both material and thickness must be considered together.

Consider the Application First

The first step in choosing the right thickness is understanding where and how the mesh will be used.

For structural or heavy-duty applications such as walkways, platforms, and machine guards, thicker expanded steel mesh or expanded stainless steel mesh is recommended. These applications require higher load capacity and resistance to deformation.

For plaster reinforcement, cladding support, and architectural panels, medium or thin expanded mild steel mesh works well. It provides sufficient strength while remaining flexible and easy to fix on walls or ceilings.

When sourcing from a trusted expanded metal mesh supplier in India, it is important to specify whether the mesh is for load-bearing use or surface reinforcement, as this determines the minimum thickness required.

Evaluate Load and Stress Requirements

Thickness selection also depends on how much load the mesh will carry. Thicker mesh is ideal for industrial flooring, stair treads, and protective barriers where constant pressure or foot traffic is expected. Thin mesh is more suitable for decorative panels, false ceilings, and ventilation screens where structural load is minimal.

For example, expanded stainless steel mesh with higher thickness is often used in chemical plants and food processing units because it can handle both mechanical stress and corrosion. In contrast, thin expanded mild steel mesh is commonly used in plastering and fencing where flexibility is more important than heavy strength.

Environmental Conditions Matter

The surrounding environment plays a major role in choosing mesh thickness. In outdoor or high-moisture environments, corrosion resistance becomes crucial. Thicker expanded stainless steel mesh offers better durability in coastal or industrial areas exposed to chemicals and humidity.

If using expanded steel mesh or expanded mild steel mesh outdoors, additional coatings like galvanization or powder coating may be required. In such cases, slightly thicker mesh is preferred to compensate for long-term wear and corrosion risk.

An experienced expanded mesh manufacturer in Pune can guide buyers on selecting the appropriate thickness based on climate and exposure conditions.

Balance Cost and Performance

While thicker mesh provides higher strength, it also increases material cost and weight. Over-specifying thickness can lead to unnecessary expense and difficult installation. On the other hand, choosing mesh that is too thin may result in bending, cracking, or reduced service life.

A reliable supplier like Zain Corporation helps customers balance performance and budget by offering multiple thickness options across expanded mild steel mesh, expanded steel mesh, and expanded stainless steel mesh categories. Their product range supports applications from light architectural use to heavy industrial requirements.

Check Industry Standards and Specifications

Always refer to standard specifications and engineering requirements when choosing thickness. Many construction and industrial projects require mesh that meets defined load ratings and safety standards. Working with a certified expanded metal mesh supplier in India ensures that the product meets these quality benchmarks.

Suppliers also provide technical data sheets showing thickness, strand width, and open area percentage, which help engineers and contractors make accurate decisions.